By now, you’ve probably heard of third-party logistics and what they can do for eCommerce sellers. But what are 3PLs, exactly? And why should you care? In this guide, we’ll break down everything you need to know about 3PLs and how they can help your eCommerce business. Keep reading to learn more!

Third-Party Logistics (3PL): What Are They?

Third-party logistics, also known as 3PL, describes outsourcing eCommerce logistics functions like inventory management, warehousing, and fulfillment to third-party companies. eCommerce sellers can save so much time and effort to accomplish more with the help of third-party logistic providers, thanks to the infrastructure and tools for automating retail order fulfillment.

The term “third-party logistics” may not have been first used. But in the 1970s and 1980s, businesses started to increasingly outsource their inbound and outbound logistics needs to outside parties.

The term “3PL” has now become commonplace. And 3PLs have increased the scope of their offerings, thanks to the development and growth of eCommerce in the 2000s. Third-party logistics is also used to describe the supply chain integration of warehousing operations and transportation services.

What Distinguishes CFA and 3PL From One Another?

There is a significant difference between the terms clearing and forwarding agent (CNA) and third-party logistics (3PL), although they are frequently used interchangeably. A business known as a clearing and forwarding agent is in charge of the paperwork and shipping of goods between nations. They are responsible for ensuring the products are delivered to the proper location and clearing them through customs.

On the other hand, a company that offers complete logistics solutions is known as a third-party logistics provider. This implies that they can manage every aspect, including fulfillment, transportation, and customer service. Although they can be included in a 3PL solution, clearing and forwarding agents and 3PL solutions are not the same.

1PL, 2PL, 3PL, 4PL, 5PL Defined

The 1pl, 2pl, 3pl, 4pl, and 5pl systems are a grouping for logistic providers. These categories describe how involved the company is in handling the client’s requests. This makes it easier to choose the right kind of offer to make sure the solutions put forth are sufficiently pertinent.

The services offered by 1pl, 2pl, 3pl, 4pl, or 5pl differ drastically. Therefore, a logistic provider can handle freight storage, product distribution, and raw material management. Additionally included in the services that some specialists offer are transportation-related operations. This relates to choosing which transportation method to use, subscribing to insurance policies, and the framework for administrative obligations.

The logistic provider may also offer integration solutions based on its 1pl, 2pl, 3pl, 4pl, or 5pl categorization. Stock management, fleet or freight localization technology, or ERP software for specific situations.

Key Differences Among 1PL, 2PL, 3PL, 4PL, 5PL

As was already mentioned, the distinction between providers offering 1pl, 2pl, 3pl, 4pl, and 5pl services depends on how essential those services are to a company:

1PL: Fundamental subcontracting for nationwide transportation services, such as product distribution and loading.

2PL: The addition of warehousing and storage services to transportation services. This is typically carried out on the premises of the mandated company.

3PL: This kind of provider provides specialized knowledge, consistent oversight, and effective communication, particularly regarding customs formalities. They also offer returns management.

4PL: These are usually consulting firms that provide integrated solutions to manage the logistics side of the supply chain. A 4PL provider also has additional resources devoted to digital tools alongside its 3PL resources;

5PL: The supplier provides engineering expertise and cutting-edge, ground-breaking flow automation systems.

The Procedure for 3PL Order Fulfillment

What happens in a 3PL fulfillment center might appear to be a mystery if you’re thinking about working with a 3PL provider or are new to outsourcing shipping.

The 3PL fulfillment procedure, however, doesn’t have to be mysterious and really shouldn’t be!

When a customer places an order on your online store and clicks “Submit Order,” what exactly happens at a 3PL’s eCommerce warehouse? Let’s examine the entire procedure from beginning to end.

Receiving

Receiving

Orders cannot be shipped by a 3PL without inventory on hand. In a 3PL warehouse, accepting incoming inventory and storing it are both considered “receiving.”

Every 3PL has unique procedures and room to receive and store inventory.

For instance, at Eva.guru, we require customers to complete a Receiving Order (RO) to specify which products and how many units we will receive. Due to our improved organization and punctuality in receiving, we are better able to begin quickly and effectively completing your orders.

Warehousing

Warehousing

3PLs store your products in 3PL fulfillment centers after they receive your inventory. Each SKU has a dedicated storage space all to itself, whether it be a shelf, a bin, or a pallet.

Storage capacities vary between 3PLs, not all 3PL warehouse space is created equal. Working with a 3PL that has more storage space than you need for your current inventory is crucial, as your product line and order volume expands, your 3PL storage must be scalable.

A 3PL is different from an on-demand warehouse matching service, which merely finds you extra space in different warehouses without running any logistics centers.

Picking

Picking

The 3PL fulfillment process can start once a customer places an order. This is the first half of the expression “pick-and-pack fulfillment,” which you may have heard before.

Some 3PLs demand that you manually upload orders to their database. Sometimes, spreadsheets are used for this, containing information about orders, customers’ shipping, and more. It may be difficult and inefficient to manage orders in this way.

Other 3PLs have cutting-edge technology that seamlessly integrates with your marketplace or eCommerce platform. These 3PL fulfillment software integrations streamline the fulfillment process for more automated shipping by bringing orders, shipments, inventory tracking and stock levels, and more into one location.

This includes immediately sending online customer orders to your 3PL after they are placed.

An order is assigned to the warehouse picking team when it is sent to your 3PL. A packing list of the items, quantities, and storage locations at the facility is given to the picker so that they can pick up the ordered goods from the appropriate areas.

Packing

Packing

Once every item in an order has been selected, it is time to pack it safely for shipping. Your 3PL’s capabilities, brand preferences, and shipped items will all affect the packing supplies used.

The most typical types of standard packaging materials are:

- branded boxes not

- bubble mailers

- bubble mailers bags

- wrapping paper

- Dunnage

- dunnage made of paper

Packing supplies may be billed separately by some 3PLs or included in their fulfillment management services by others. The 3PL will select the best packaging materials as skilled shippers to safeguard your products and achieve the lowest practical dimensional weight. Additionally, they will optimize your packages so you won’t need to divide shipments. Dimensional weight is a method of calculating shipping costs considering the package’s size. Logistics costs can be reduced by using the proper packing materials.

Make sure you collaborate with a 3PL that permits you to use custom packaging, such as custom boxes and inserts if you want your brand to be seen through your shipping. Branded packaging can leave a lasting impression on customers, especially since receiving a package is frequently their first in-person interaction with your company.

Shipping

Shipping

Your order will be shipped after this. On your behalf, most 3PLs will buy and print shipping labels. While some 3PLs compare shipping prices from various carriers, others have preferred carrier partners. The latter enables 3PLs to provide customers with the most competitive pricing for the delivery speed that each customer selects.

Orders are picked up from 3PL warehouses and shipped by carriers like DHL, USPS, and UPS. Each order’s carrier and shipping speed are determined by the 3PL’s policies and partnerships, as well as the client’s shipping options and the end user’s choice. When an order is shipped, 3PLs equipped with the integrated technology mentioned above will immediately send the tracking information to the online stores of the merchant.

Returns

Returns

Additionally, many 3PLs provide return processing services. If a customer returns an order to your 3PL, they will process the return and, based on their policies and preferences, either restock the item or dispose of it.

You have the option of having your 3PL offer return shipping labels to your clients. Customers can easily track the status of their return order, and you won’t have to handle returns internally, which is convenient for both of you.

How Can Third-Party Logistics Help Amazon Sellers?

Businesses outsource logistics tasks, not core business operations, to third-party logistics providers. Suppliers focusing on logistics can frequently provide transportation and warehousing services for less money and with better results than businesses with in-house operations. A company can boost customer satisfaction with its products while relying on third parties to fulfill orders adequately when it can obtain high logistics service levels from suppliers.

Focus

Focus

Because it takes time and resources from the company to plan this intricate but common business function of getting goods to customers, logistics can be a diversion from a company’s core business. Third-party logistics providers are experts in shipping, warehousing, and inventory control. They can concentrate on their areas of expertise while you concentrate on raising customer satisfaction while producing a high-quality product. Your staff can focus more on ensuring customers receive high-quality goods and excellent service when freed from having to deal with trucking companies and inventory tracking.

Efficiency

Efficiency

Using economies of scale, third-party logistics providers can deliver your products faster, reduce inventory with more frequent deliveries, and track inventory in warehouses more efficiently. Your business is no longer required to rent a warehouse and utilize only a portion of it or maintain insufficient inventory due to a lack of room. As your space needs change, a logistics provider bills you for the space you use while maintaining the right amount of inventory. When logistics are run more effectively, production is more dependable, and customer satisfaction is higher because customers receive their orders on time.

Flexibility

Flexibility

Third-party logistics providers now have more resources, allowing you to better assess how to satisfy your customers with higher service levels. Imagine you wanted to gain a competitive edge by utilizing next-day delivery. In that case, you could discuss the options and associated costs with your logistics provider, who is equipped to carry out such strategic plans. If you’d like to experiment with just-in-time delivery of the needed materials, your logistics provider can accommodate your requests. You can respond to changes in customer needs more quickly with a more adaptable supply chain, which increases customer satisfaction.

Data-Driven Technology

Data-Driven Technology

On both the supply and delivery sides of your operations, information technology enables the tracking of shipments, materials, and goods. Such systems are expensive to maintain and require technical personnel with specialized training. You can get information on the locations of crucial deliveries from third-party logistics providers, which will help you plan your production more accurately.

Deliveries to customers can be tracked more effectively. The resultant streamlined operations enable prompt problem diagnosis and customer-satisfactory resolution while putting products in customers’ hands quickly and reliably.

More Satisfied Customers with Third-Party Logistics!

According to the 2017 Third-Party Logistics Study, 89% of shippers believe that using a 3PL enhances customer service. That level of assurance makes it obvious that a third-party logistics provider must provide a number of benefits, but what are they?

1. Professional service

Customers of today anticipate a seamless shopping experience, whether it be online, on a mobile device, etc. According to studies, 90% of consumers who interact with brands expect a consistent customer experience across channels and devices. Additionally, they want a selection of delivery and in-store pickup options.

You can deliver with the aid of a 3PL with an effective order management system (OMS). They can help you optimize your inventory so you can fill orders from various sources (DCs, stores, vendors). This makes it simpler to provide customer-friendly services like online ordering and buying online, picking up in-store.

Their familiarity with best practices and omnichannel experience also contribute to ensuring that your customers have the same experience whether they purchase in-person, online, or over the phone.

2. Increased order accuracy and visibility

Customers expect to know whether the products they want are available both online and in stores, as well as when they will receive them when they shop online. When a retailer’s website does not display the most recent product availability, 80% of customers are less likely to visit the physical location. When orders are delivered, customers anticipate getting the requested item, quantity, and color. That is not an excessive request.

Here too, a 3PL can be useful. They will be able to give you accurate, up-to-date inventory information with an OMS so you can see what is in stock, what is on backorder, etc. Additionally, they will have the most recent order status and tracking data.

A 3PL that prioritizes quality will give careful consideration to solution design and incorporate tried-and-true procedures to help guarantee order accuracy. So that your service level keeps improving, they will use methodologies like Lean and Six Sigma to find opportunities for improvement.

3. Cost-effective, quick deliveries

It goes without saying that today’s consumers want their goods quickly and affordably. According to a recent Deloitte study, nearly 90% of consumers believe that free shipping is even more crucial than fast shipping, but only 35% and 35%, respectively, will wait three to four days for their orders to arrive.

How can your 3PL facilitate such a quick turnaround? They will be able to process orders more quickly and find the fulfillment source that is closest to the customer for quick delivery with the aid of their trusted OMS. Additionally, they are probably equipped with material handling machinery and automation systems that can speed up order turnaround times.

Especially if you use multiple DCs, your 3PL probably also has a network of strategically placed facilities that can put your products within a simple, two-day ship time from your customers using less expensive ground service. Their negotiating power and well-established carrier network will give them the freedom to choose the best mode and level of service for each shipment. By negotiating prices, pooling parcel deliveries, and utilizing postal work-share options like presorting and drop-shipping, they can also help you save on outbound freight costs.

4. Individualization

One of the biggest benefits of today is personalization. Customers want to personalize their purchases, whether through embroidery, engraving, or specialty packaging and gift wrapping. Delivering on your promises will probably boost sales, foster customer loyalty, and help you stand out in the crowd. These kinds of unique touches can be time-consuming, though. This is yet another excellent chance to use your 3PL.

Your third-party provider can assist you in expanding your product offerings without carrying an excessive amount of inventory thanks to a wide range of value-added services. A 3PL can put off product configuration until the very last minute thanks to their flexible space and labor, which enables you to better meet customer demand. Facilities that are well-placed can also move these services closer to the client to speed up the process.

5. Prompt service

Customers demand excellent service. According to a Spark response study, 65% of consumers have severed ties with a brand following a single negative consumer experience. You need all the assistance you can get under that kind of performance pressure.

A 3PL can be a helpful partner. Even during busy shopping seasons like Black Friday and Cyber Monday, their vast resources (including space, labor, technology, and locations) will give you more flexibility to handle an increase in order volume without losing a beat. To handle customer issues more quickly and streamline returns, they might provide a call center. As part of their dedication to quality management, they will constantly seek out fresh approaches to enhance operations and satisfy your clients.

Since the COVID-19 Pandemic, How Has Third-Party Logistics Changed?

As a result of the sudden need to change how they operated, more businesses are using 3PLs to fulfill orders on their behalf. Demand increased dramatically across the board, and e-commerce growth experienced a boom that has since stabilized as a new normal.

But it wasn’t just a general increase in industry demand. The pandemic also had other knock-on effects, and logistics service providers had to continuously adjust to new business environments, work environments, and customer behavior. Additionally, they had to adapt to specific travel and work restrictions in their respective regions, which required managing their fleet and human resources differently.

The level of demand and the industry’s makeup have undergone these sudden and abrupt changes over the past few years (B2B vs B2C). Businesses want to shift away from fixed costs like managing their own logistics, renting their own facilities, and hiring their own staff in favor of variable costs and add more flexibility to their supply chains so they can react quickly to these changes. 3PLs are the ideal partners to assist them in doing this as well as improving the overall experience for their clients.

The worth of 3PL companies is also increasing. Businesses use 3PLs because they have realized that the cost of owning and operating their own warehouse is frequently much higher than storing inventory at a 3PL. In addition, they gain from the 3PL’s status as a dedicated logistics provider, which means that it has skilled personnel and can offer high-quality services.

The thing is, with the right automated processes and optimized processes, 3PLs can provide experienced staff and access to established networks on a large scale for many businesses at a reasonable price.

The general public is much more knowledgeable about the 3PL industry. Before the pandemic, unless you were in logistics, nobody would have known that we made software for the third-party logistics (or 3PL) industry. More than ever, the general public is aware of the 3PL sector and is aware that certain logistics companies handle transportation and storage on behalf of other companies.

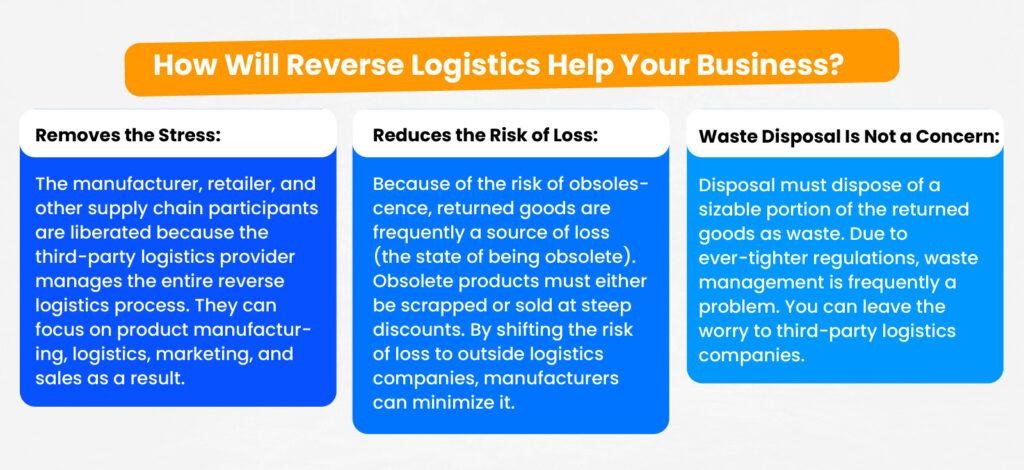

Reverse Logistics, What Is It?

More shippers are outsourcing their supply chain to third-party logistics firms as hassle-free shipping services become an integral part of the purchasing experience for customers. The flexibility and scalability of 3PLs are well known; these qualities are essential in today’s e-commerce, especially concerning product returns. Learn how outsourcing reverse logistics functions can benefit your business as it affects everything from budget spending to sustainability:

The phrase “last-mile delivery” is frequently used when discussing supply chain solutions. However, the supply chain is cyclical, as we all know. Services involving the transportation, repurposing, and disposal of goods are all included in reverse logistics. Processes that take place after the customer receives the product, you know. Think:

- faulty products

- Recalls of products

- return of a warranty

- Items returned

- Reusable packaging/containers

- Useful products

- Seasonal products

- hazardous substance

The Reverse Logistics Process

Customer Support:

Customer Support:

This is the first step in reverse logistics, including customer support over the phone, by email, through online chat, and in other ways. The intention is to maintain open lines of communication for clients who might want to repair or return the faulty item they have purchased.

Receiving the Product:

Receiving the Product:

Either the retailer will accept defective products returned by customers, or the manufacturer will recall any defective products (via its retailers). The customer has three options for returning the item: personally, jointly with someone else, or by mail. Sometimes manufacturers or retailers will also pick up the product from the customer.

Product transportation involves returning the recalled or returned goods to the manufacturer. This could require just one step (from the retailer to the manufacturer) or several steps (retailer to the dealer, distributor to the manufacturer). The mode of transportation may be land, air, or sea, depending on the kind, weight, and distance of the item to be transported.

The product is tagged, tracked, and stored in a warehouse with other returned goods after it has reached the manufacturer’s facility. A warehouse is a sizable storage area frequently furnished with tools for tagging and tracking the items kept there.

Sorting the Products:

Sorting the Products:

The products are sorted or triaged depending on their condition and quality (to use the correct term). The appropriate department receives products that can be repaired and repairs them. Unrepairable goods are sold at a much lower price than defective goods or scrapped.

Repair:

Repair:

If a product that has been returned is determined to be in good enough condition for repair, it is fixed and either sent back to the customer or sent back to be sold to another customer. Products are occasionally refurbished and sold at significant markups, bringing the manufacturer a profit.

Many manufacturers contract out their reverse logistics to third-party logistics companies that receive customer-returned goods, repair and refurbish them, and then resell them at deep discounts. The refurbished product is frequently sold by third parties at a higher markup than the original markup, making a sizable profit.

Using Third-Party Logistics for Omnichannel Sales

Both B2B and B2C fulfillment have very different needs, volumes, levels of predictability, and levels of urgency. Instead of developing a master fulfillment strategy for various sales channels, many businesses keep these operations separate, with various distribution structures and strategies.

This is incorrect. Today’s world is multi-channel. For all of your sales channels, you need a unified distribution strategy that concentrates on managing the “three I’s” of inventory, infrastructure, and information if you want to be profitable in this world.

Differences between B2B and B2C

The volume, predictability, urgency, and demand requirements for B2B and B2C operations vary. With a high frequency of similar orders handled daily or multiple times daily, B2B fulfillment is highly predictable. To reduce inventory, cut costs, and implement customization and special projects as needed, B2B operations turn to 3PL providers. Due to the business’s focus on volume, less labor is required for each saleable unit. The fact that B2B customers are professionals who buy and sell things dictates that every fulfillment step must be carried out perfectly.

B2C fulfillment is less predictable because it fluctuates with consumer behavior. Due to the need for picking and packing each individual customer order rather than picking pallets for retail replenishment, there is more 3PL labor required per saleable unit. Successful 3PL partners can navigate the volatile demand, irregular activity, and volume spikes inherent in B2C operations.

Using One 3PL to Handle Multiple Sales Channels at Once

Despite these variations, many 3PLs can work together to serve various channels through a single, well-coordinated fulfillment strategy. How? They must first have the room, personnel, skills, and capacity to manage each channel separately. Then, handling both simultaneously can be as simple as combining both operations into a single, massively coordinated operation. That is only possible if the foundation is set up correctly from the beginning.

Whether B2B, B2C, or both, the success or failure of these fulfillment operations largely depends on the service level agreements (SLAs) established at the very beginning of the relationship. The level of service expectations for quality, throughput, timeliness, execution, inventory, receipt, shipping, and other fulfillment components are clearly understood by SLAs. SLAs allow all parties to proactively manage the fulfillment operation while defining roles and evaluating performance.

The 3PL can then start working on optimizing your inventory, infrastructure, and information once the foundation has been laid.

3 Most Important Areas that Third-Party Logistics Cover For You

Inventory

Inventory

The amount of inventory needed throughout your distribution network decreases by storing the inventory for all your sales channels together. Assume you maintain separate channels and store your B2C inventory in three locations and your B2B inventory in three additional locations. There are six different places where you must maintain inventory, which necessitates more stock to maintain an adequate supply, raising costs and raising the possibility of being left with unsold goods.

You could use various inventory management systems and different teams to carry out your SLAs with this “separated” model.

In contrast, if you consolidate your inventory for both channels at three 3PL locations, you need less inventory, fewer employees, and a single nationwide system for managing your inventory.

You can collaborate with a 3PL to identify the products you’ll need for each channel, where you’ll need them, and when using sales forecasts and historical data. To assist you in maintaining the optimal levels of your inventory and labor force, that partner should also offer prompt, accurate reports on orders and fulfillment activity.

Infrastructure

Infrastructure

You can fulfill B2B and B2C orders from the same warehouses and inventory pool thanks to a partnership with a skilled 3PL. The stock is physically separated into areas in the same warehouse, with the bulk replenishment area housing most of the stock. An individual warehouse management system (WMS) directs products into two forward-pick areas as forecasts determine future demand and actual orders.

With this strategy, you can maintain just the right amount of inventory to satisfy demand across all sales channels. A nationwide network of facilities managed on a single system for network-wide visibility characterizes a 3PL well suited to this strategy. You can meet strict delivery requirements for customer orders using such a network while also minimizing freight costs.

Information

Information

You can use one system to have end-to-end visibility into your entire supply chain by working with a 3PL to handle fulfillment for various sales channels. Real-time data on inventory management, order management, and shipping/tracking management enables you and your 3PL to make proactive workflow and decision-making decisions while also keeping your customers informed.

This strategy will also prepare you for the unavoidable day when all retail establishments turn into satellite distribution centers (DCs), shipping orders to local customers or holding them for in-store pickup.

Look for the following when selecting a partner to support multiple sales channels:

- strong background in direct-to-consumer fulfillment and retail replenishment

- National fulfillment facilities are all controlled by a single system for network visibility

- Solutions that are specifically tailored to meet your needs

Today’s consumers anticipate being able to purchase anything they want through any channel they choose. Don’t let that, however, affect how effectively your fulfillment network operates. Create a multi-channel fulfillment strategy that makes your fulfillment processes simpler and more efficient.

What Part Does Third-Party Logistics Play in eCommerce?

Supply chains are becoming more complicated in the world of eCommerce today. Third-party logistics (3PL) play a role in this. In general, a 3PL can handle anything that needs to be done to move a product from Point A to Point B. Thus, 3PLs are essential to the supply chain for online retailers. They assist companies in contracting out their logistics requirements to concentrate on other activities, such as product sales and client relations.

Amazon is the ideal illustration of a business that successfully utilizes 3PLs. By using 3PLs to manage its supply chain requirements, Amazon has grown into a sizable company. Don’t undervalue the part that 3PLs can play in your success if you’re in the eCommerce industry.

How Can I Find a Good 3PL Company?

Having a strong supply chain is crucial if you work in the eCommerce industry. Finding a reliable 3PL business is also essential for success if you sell on Amazon. But how do you locate a reliable 3PL firm for your Amazon business?

When picking a 3PL company, there are some things to keep an eye out for. Initially, confirm that they have prior Amazon business experience. Check their references and reviews next. Third, find out whom other Amazon sellers use by talking to them and finding out what 3PL services they need.

Compare prices and services once you’ve narrowed your search to a few viable choices. Make sure you are aware of the costs each company charges. Also, make sure to enquire about issues like customer service and shipping times. You can discover the ideal 3PL provider for your Amazon business by conducting research.

How Does a 3PL Supply Chain Become Profitable Over Time?

A supply chain is only as strong as its weakest link, and logistics are that weak for many companies. Third-party logistics, or 3PL, fortunately, offers a remedy. 3PL companies specialize in managing the supply chain and can offer your company many benefits, including cost savings, increased productivity, and increased flexibility. Working with a 3PL over the long haul can be very profitable for your Amazon business. You’ll be able to concentrate on selling products, which is what you do best, while also saving money on shipping and fulfillment expenses. Your products will always arrive on time and in perfect condition if you work with a dependable 3PL partner so that you can relax. So, if you want to grow your Amazon business, think about working with a 3PL provider.

What Obstacles Must Third-Party Logistics Overcome?

A few of the difficulties faced by 3PL businesses to succeed in the modern economy include fluctuating fuel prices, a talent shortage, poor teamwork, and shifting regulations:

Rising costs of fuel

Rising cost of fuel affects all companies that operate delivery services. Since high fuel costs can quickly reduce a company’s revenue, they constitute a significant portion of many businesses’ operating costs.

Discovering New Talent

Getting new talent into the field is one of the major issues it has. Many businesses lament the difficulty in filling open positions with qualified candidates because many lack the necessary training or experience.

The fact that there is a driver shortage in the transportation sector and has been for some time doesn’t help. The American Transportation Research Institute (ATRI), which conducts a yearly survey of industry participants to determine their top concerns, has consistently ranked driver shortage as one of its top five issues.

For 3PL companies, whose margins typically can’t withstand efficiency declines, the lack of qualified talent leads to a loss of productivity and efficiency.

Failure to Work Together

It is impossible to overstate the importance of transporters’ and carriers’ roles in supply chain management. However, their significance is frequently disregarded at the operational level. Carriers, shippers, and customers’ lack of cooperation harms the supply chain’s efficiency, to say nothing of their lack of communication or supply chain integration.

Rules of the Government

Majority of 3PL companies transport goods between different cities, states, and even nations. As a result, they are required to follow the laws and ordinances of these various areas. Government regulations differ from one city or state to the next, and 3PL fulfillment businesses must stay current and comply with all of these laws to continue operating successfully. As much 3PLs lack access to adequate human resources to manage and keep track of the changing and varying regulations, this is a difficult task.

Environmental Issues

Concerns about how transportation affects the environment are becoming more widespread. Players in the industry are concerned about local and state regulations against idling and emission reduction. If businesses don’t find a cost-effective way to cooperate, following these regulations may end up costing them money.

Customer requirements

Meeting each client’s needs is a challenge many 3PL firms face because client requirements differ greatly from company to company. A major headache for 3PLs that haven’t kept up with technology is the growing customer demand for quick shipping and real-time visibility on delivery status.

There are no trustworthy reporting mechanisms.

Keeping track of all the shipments being sent out can be challenging for even mid-sized 3PLs. It can be challenging to ask vendors about shipments made to create a monthly statement. Because manually tracked inventories and shipments are prone to human error, the absence of a reliable reporting system can force 3PLs to absorb high labor costs and even revenue losses.

Conclusion

If you’re looking for a way to take your online business to the next level, third-party logistics may be just what you need. Thanks to the ever-growing popularity of eCommerce, 3PL providers have expanded their offerings and infrastructure to accommodate retailers of all sizes. Eva’s 5-star 3PL Logistics is here to help you boost your sales and streamline your fulfillment process. Eva is one of the preeminent Amazon advertising agencies with the perfect solution for your business.

Contact us today to learn more about how we can help you take your business to new heights!

Community

Community