Paperless picking is a warehouse picking method that replaces paper picking lists with digital instructions. Instead of printing paper documents and handing out paper lists, companies use a paperless picking system that delivers real-time instructions through mobile devices, electronic shelf display panels, or hands free headsets.

For many warehouses, paperless picking is not just a “nice upgrade.” It is an operational shift that reduces human errors, shortens time spent searching, and improves order fulfillment speed — especially when order volume is high and SKU variety is wide.

MAIN IDEA: Paperless picking modernizes the picking process by turning paper picking into digital systems with real-time order data, verification, and immediate feedback.

What is paperless picking?

Paperless picking is a picking process where the order picker receives a digital picking list instead of physical documents. The system sends digital instructions to employees and confirms each pick via barcode scanning, visual confirmation, or voice confirmation.

This approach helps many warehouses build efficient processes around order picking and inventory updates. Paperless picking also supports faster processing, shorter delivery times, and higher picking performance.

Paper picking vs Paperless picking (simple difference)

With paper picking, the picker follows printed paper lists, marks quantities on paper documents, then returns for data entry. That creates delays, counting errors, and mix ups.

With paperless picking, order data is transmitted electronically, and the picker is guided directly to the correct storage location. That typically reduces error rate and improves increased efficiency.

KEY POINT: Paperless picking replaces paper documents with digital systems that can verify a wrong item before it reaches packing.

Why companies switch to paperless processes

Companies adopt paperless processes to improve accuracy, speed, and scalability.

Paperless picking helps when:

- order volumes grow quickly,

- seasonal fluctuations create peak periods,

- new employees need to be onboarded fast,

- the warehouse layout is complex,

- customers expect short delivery times.

By eliminating paper from picking operations, companies also reduce environmental impact.

How a paperless picking system works

A paperless picking system typically connects three layers:

- Order transmission (order data from ERP/WMS)

- Execution (picking systems and digital devices that guide the picker)

- Verification & updates (barcode scanners / RFID, inventory updates, and immediate feedback)

In practice, paperless picking works best when order data is clean and item locations are maintained consistently.

Digital systems used in paperless picking

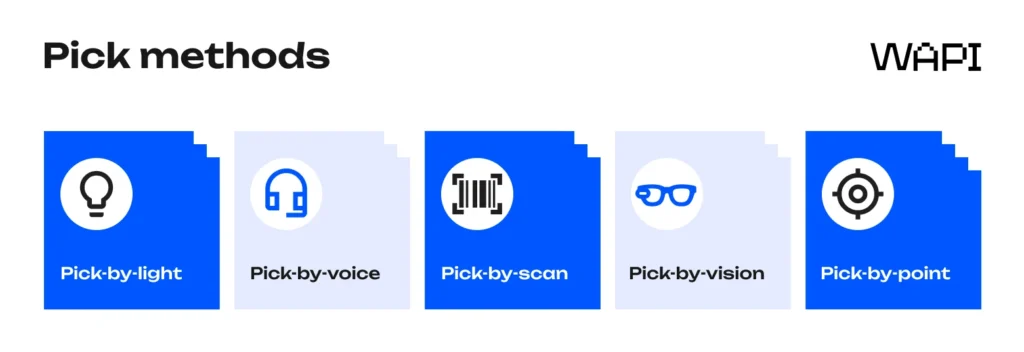

Digital systems in paperless picking rely on fulfillment software to transmit electronic order data, deliver real-time instructions to pickers, and synchronize confirmations with inventory updates. But they can do it in different ways. The most common paperless picking methods include:

- pick by light (pick-to-light)

- pick by voice (voice picking)

- pick-by-scan (handheld scanners)

- pick-by-point (light beam guidance)

- pick-by-vision (data glasses / AR overlays)

These automated systems are designed to make picking more suitable for high-speed operations without relying on paper lists.

Pick-by-light: fast guidance with electronic shelf display

Pick by light systems guide the picker using LED indicators at the storage location. The picker sees where to pick and receives immediate feedback once the pick is confirmed.

In many setups, an electronic shelf display shows quantity and location. Confirmation can be done via button press or barcode scanning.

Advantages of pick by light:

- very fast picking performance,

- clear visual guidance,

- lower time spent searching.

Trade-offs:

- requires infrastructure on shelves,

- best for stable layouts and repeated picks.

Pick-by-voice: hands free warehouse picking

Pick by voice is a paperless picking method where the picker receives digital instructions through a headset and confirms actions verbally. This hands-free workflow can improve workplace safety by reducing unnecessary movement and keeping both hands available for goods and material movements.

Voice picking is suitable when:

- the warehouse has long aisles,

- items are varied,

- pickers need mobility without holding mobile computers.

Pick-by-scan: mobile devices and barcode scanners

Pick-by-scan is one of the most common paperless picking methods. The order picker receives a digital picking list on mobile devices or mobile handheld computers. They then scan items with barcode scanners to confirm correctness.

Barcode scanning helps reduce human errors such as wrong item picks, incorrect quantities, and mix ups. It also supports error reduction through automatic verification.

Typical tools:

- handheld scanners,

- mobile computers,

- barcode scanners integrated into a digital picking system.

Pick-by-point and pick-by-vision (advanced options)

Pick-by-point systems use a light beam to point to a shelf location. The picker confirms via barcode scanning. This can combine the clarity of light guidance with scan verification.

Pick-by-vision uses data glasses (augmented reality). The system overlays digital instructions in the picker’s field of view. This can reduce time spent searching and increase picking performance, but hardware selection and change management matter a lot.

Paperless picking and Warehouse Management System integration

The integration of paperless picking systems with a warehouse management system is crucial.

A strong warehouse management system enables:

- electronic order transmission,

- real-time instructions,

- real time tracking,

- inventory updates after each pick.

Without WMS integration, paperless systems often become “digital paper” — better than paper lists, but still limited.

OUR ADVICE: Treat the warehouse management system as the control layer. Paperless picking devices are execution tools.

Real-time inventory visibility and inventory management

One major advantage of paperless picking is real-time inventory visibility. Each scan (or confirmation) updates inventory levels and stock levels instantly. This is especially valuable when fulfillment spans multiple markets, helping prevent overselling and keep order data consistent across cross border logistics operations.

Paperless picking systems provide real-time visibility that helps companies:

- manage inventory and stock levels,

- reduce counting errors,

- optimize replenishment timing,

- improve order fulfillment planning.

Advantages of paperless picking (business + operations)

Paperless picking offers both direct and indirect benefits.

Advantages of paperless picking for operations

- reduced time spent searching,

- increased efficiency across picking processes,

- fewer human errors and lower error rate,

- better picking performance through guidance and verification.

Advantages for costs and ROI

Implementing paperless picking system technology can deliver cost savings in two ways:

- direct savings: less paper, printing, storage, and document processing

- indirect savings: improved labor efficiency and fewer errors

Many companies measure ROI by tracking:

- picking accuracy,

- order processing times,

- order fulfillment cycle time,

- error rate reduction.

Paperless picking helps new employees ramp faster

Paperless picking helps because it reduces reliance on “tribal knowledge.” When digital instructions guide employees to a correct storage location, training time decreases.

User-friendly picking systems are especially valuable when:

- turnover is high,

- seasonal fluctuations require temporary staff,

- new employees must reach productivity quickly.

What to consider before implementing paperless picking

The most suitable manual picking method depends on:

- warehouse size,

- order quantity,

- type of item,

- warehouse strategy,

- layout complexity.

Hardware selection should match pick speed needs and mobility requirements. For example, a freezer environment may require rugged devices, while high-speed zones may benefit from pick by light.

Implementation approach: phased rollout (recommended)

A phased rollout approach is usually the safest path.

5 steps of paperless picking implementation

- Pilot program: choose one zone or product family

- Device setup: select mobile devices, handheld scanners, or light systems

- WMS connection: ensure real-time data exchange and stable order data

- Training: develop training programs and SOPs

- Scale: expand to more picking processes and picking systems

This reduces disruption and helps validate ROI before full rollout.

Training and change management

The transition to paperless picking requires careful planning.

Training programs should cover:

- device usage,

- barcode scanning routines,

- exception handling (damaged barcode, missing stock),

- verification steps to prevent mix ups.

Change management matters because paperless processes are new habits, not just modern technologies.

KPI tracking after go-live

Monitoring KPIs is essential for continuous optimization.

Track:

- pick speed (picks per hour),

- time spent searching,

- error rate and counting errors,

- order fulfillment time,

- inventory levels accuracy.

This KPI loop helps companies improve efficient processes and sustain increased efficiency.

Common risks (and how to avoid them)

Paperless picking offers strong benefits, but it is not “plug and play.”

Typical issues:

- poor item locations data,

- outdated storage location mapping,

- weak barcode standards,

- insufficient training for employees.

Fix: start with inventory discipline and stable master data, then expand paperless systems.

Is paperless picking suitable for every warehouse?

Not always.

Paperless picking is most suitable for:

- high order volume,

- variable products,

- many warehouses with fast turnaround needs,

- operations where errors are costly.

It may be less suitable when:

- order volume is very low,

- items are oversized and manual handling dominates,

- processes are highly customized and slow anyway.

TRUST NOTE: The best picking method is the one that fits the warehouse strategy — not the most “innovative solutions” on paper.

Final takeaway

Paperless picking replaces paper picking lists with digital systems that guide pickers using mobile devices, electronic shelf display tools, or voice picking. Verification via barcode scanning (or RFID) reduces human errors, improves inventory management, and supports real-time order fulfillment decisions.

When a paperless picking system is integrated with a warehouse management system, warehouses gain real-time tracking, better inventory levels control, and faster processing — often leading to cost savings, fewer errors, stronger final mile delivery performance and customer satisfaction.

Community

Community