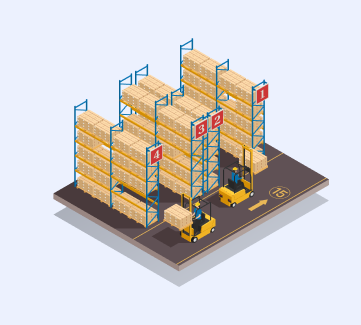

Warehousing is an indispensable component of the supply chain, acting as the linchpin for the storage, handling, and distribution of goods. The logistics landscape encompasses different kinds of warehouses, each serving distinct purposes and contributing to the global movement of products. This expansive article extends the exploration of the diverse world of warehouses, encompassing additional types, classifications, and a detailed analysis of their functions within the logistics framework. Understanding warehouse classifications is crucial for businesses seeking to optimize their supply chain and storage strategies. Exploring the various types of warehouses and their functions is essential for companies aiming to streamline their supply chain operations and improve overall logistics efficiency.

Different Types of Warehouses

Distribution Centers

Distribution centers, pivotal in the supply chain, expedite the sorting and distribution of goods. Their role is critical in ensuring the timely delivery of products to their designated destinations.

Temperature-Controlled Warehouses

Specifically designed for goods with temperature-sensitive requirements, these warehouses preserve the quality of items such as pharmaceuticals, perishables, and chemicals by maintaining precise temperature levels.

Bulk Storage Warehouses

Serving as repositories for large quantities of goods, bulk storage warehouses handle commodities like grains, minerals, and raw materials, often stored in bulk containers or pallets

Retail Warehouses

Positioned strategically near urban centers, retail warehouses are optimized for rapid order fulfillment, playing a pivotal role in supporting the growing demands of e-commerce operations.

Public Warehouses

Public warehouses, operated by third-party logistics providers, offer temporary storage space to businesses lacking the resources for independent facilities. These warehouses provide flexibility, but businesses may have limited control over storage conditions due to shared spaces. Businesses often tailor their logistics strategies based on specific warehouse categories to enhance efficiency and meet diverse storage needs.

Private Warehouses

Contrary to public warehouses, private warehouses are owned and operated by a single company. This ownership offers greater control over storage conditions and processes, enhancing product quality and reducing the risk of damage or loss.

Cold Storage Warehouses

Cold storage warehouses use advanced refrigeration and temperature control systems to store perishable goods and temperature-sensitive products. Maintaining consistent temperatures in different chambers or rooms poses a challenge but is essential for preserving the quality and freshness of products.

On-Demand Warehouses

On-demand warehouses, also known as flexible or shared warehouses, provide businesses with access to temporary or short-term storage space. Particularly beneficial for small companies or e-commerce retailers with fluctuating inventory levels, on-demand warehouses offer scalability without the need for long-term leases.

Different Types of Warehouse in Logistics

Cross-Docking Facilities

Streamlining logistics processes, cross-docking facilities minimize storage needs by facilitating direct transfers from inbound to outbound transportation, reducing handling and storage costs.

Transshipment Warehouses

Acting as intermediate points in the supply chain, transshipment warehouses temporarily store goods before forwarding them to their final destinations, optimizing transportation routes.

Automated Warehouses

With advancements in technology, automated warehouses deploy robotics and sophisticated systems to enhance efficiency, streamline processes, and minimize the need for human intervention.

Consolidation Warehouses

Consolidation warehouses optimize transportation costs by consolidating goods from different sources into larger shipments, ensuring efficient resource utilization.

Smart Warehouses

Smart warehouses leverage the latest technologies, including IoT devices such as sensors, RFID tags, and beacons, to collect real-time data on inventory. Automation technologies, such as robotics, enhance the speed and accuracy of different kinds of warehouses operations. Safety features, including machine vision and proximity sensors, ensure worker and equipment safety.

Hazmat Warehouses

Hazmat warehouses specialize in storing hazardous materials, adhering to strict regulations and safety standards. Specialized storage systems, ventilation, and fire suppression systems minimize the risk of spills, leaks, or fires.

Warehouse Classifications and Categories

Final Mile Delivery Centers

Strategically positioned near urban areas, final mile delivery centers play a crucial role in the last leg of the delivery process, ensuring timely and accurate deliveries to end consumers.

Fulfillment Centers

Dedicated to processing and shipping online orders, fulfillment centers are at the heart of the e-commerce supply chain, equipped to handle a high volume of individual orders efficiently.

Government Warehouses

Owned and operated by government agencies, government warehouses store a wide range of goods, including military equipment, emergency relief supplies, and items seized or confiscated by law enforcement agencies.

Bonded Warehouses

Bonded warehouses store imported goods awaiting customs clearance or goods intended for export. Duties and taxes are deferred until the goods are released for sale or export, providing flexibility for businesses.

Warehouses Across Different Regions

Warehouses in Europe

Europe boasts a diverse range of warehouses addressing the unique logistics needs of the region. From traditional distribution centers to advanced automated facilities, European warehouses significantly contribute to the efficiency of the global supply chain. Fulfillment centers in Europe are strategically positioned hubs that streamline the processing and shipment of online orders, ensuring efficient and timely deliveries to customers throughout the continent. Fulfillment in Europe involves strategically located centers that efficiently process and dispatch online orders with appropriate waybills, contributing to the seamless distribution of goods across the diverse markets within the continent.

Warehouses in the UK

The United Kingdom hosts a variety of warehouses, specializing in retail distribution, cross-docking, and fulfillment centers. These warehouses are pivotal in supporting the dynamic retail landscape in the UK. Fulfillment centers in the UK serve as crucial nodes in the e-commerce supply chain, facilitating the rapid processing and delivery of online orders to meet the dynamic demands of the British market.

Warehouses in the USA

With a vast network ranging from large-scale distribution centers to specialized facilities, the United States warehouses play a crucial role in meeting the demands of the booming e-commerce industry. Fulfillment centers in the USA play a pivotal role in the e-commerce supply chain, efficiently processing and shipping online orders to meet the demands of consumers across the country

Warehouses in Germany

Germany, positioned as a central hub in Europe, accommodates warehouses serving both domestic and international logistics needs. The country’s strategic location makes it an ideal base for fulfillment centers in Germany and distribution hubs.

Conclusion

In conclusion, the warehouse landscape is diverse, addressing dynamic supply chain demands. This exploration reveals myriad types, classifications, and functions crucial for optimized operations, reduced costs, and enhanced customer satisfaction.

Navigating the logistics landscape requires a nuanced understanding of various types of warehouse in logistics. From distribution centers to specialized storage facilities, each type caters to unique industry needs, emphasizing adaptability in the modern supply chain.

Choosing the right category of warehouse is a strategic decision impacting a company’s operational efficiency. Tailoring choices based on factors like storage capacity and location ensures warehouses align with organizational logistics objectives, contributing optimally to the supply chain.

Let’s remember these types of warehouses:

- Distribution Centers

- Temperature-Controlled Warehouses

- Bulk Storage Warehouses

- Retail Warehouses

- Public Warehouses

- Private Warehouses

- Cold Storage Warehouses

- On-Demand Warehouses

Overall, in the dynamic logistics field, different types of warehouses are vital for success. Whether focusing on final mile delivery centers or adopting smart warehouses, businesses must strategically align warehouse choices with modern market demands.

Community

Community