If you run an online store, you have probably asked yourself what is fulfillment and why everyone says it can make or break your brand. In simple terms, fulfillment refers to the complete process of receiving products, storing them in a warehouse, processing orders, packing parcels, shipping them and delivering them to customers. For many online businesses, this end-to-end workflow is handled by specialized fulfillment services that improve efficiency and reduce operational complexity.

This means fulfillment is more than just logistics — it is a strategic tool that enables business growth, reduces operational complexity, and supports scalability.

This short fulfillment definition will focus on real operations rather than abstract theory. In this guide we look at the meaning of fulfillment in modern logistics, explain the key components, and show how smart businesses use fulfillment services as a growth tool rather than a bottleneck.

Fulfillment Refers to More Than Just Shipping

In the wider ecommerce supply chain management, fulfillment sits between production and last mile delivery:

- Upstream, manufacturers plan stock, raw materials and production.

- Downstream, carriers and couriers take care of the shipment and final hand-over to the buyer.

- Fulfillment connects these 2 stages through a set of tightly linked logistics processes and information flows.

From a practical point of view, fulfillment refers to everything that happens after a customer clicks “buy”:

- systems capture the order;

- inventory is reserved;

- warehouse teams pick, pack and ship orders;

- parcel networks handle the rest.

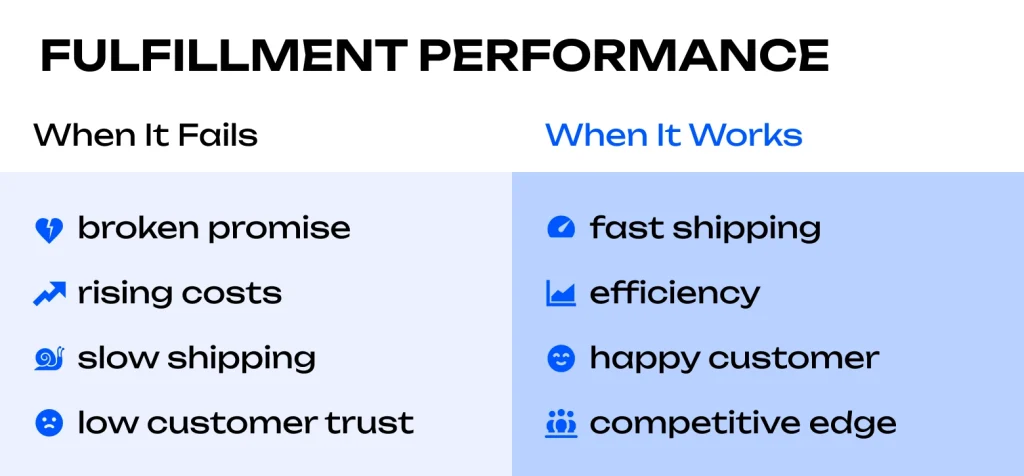

For online shops selling across borders, the way a company designs this system determines service levels, shipping costs, and the overall customer experience. When fulfilment fails, costs rise, promises are broken, and customers lose trust. When fulfillment performs well, the company gains speed, efficiency, and a competitive edge.

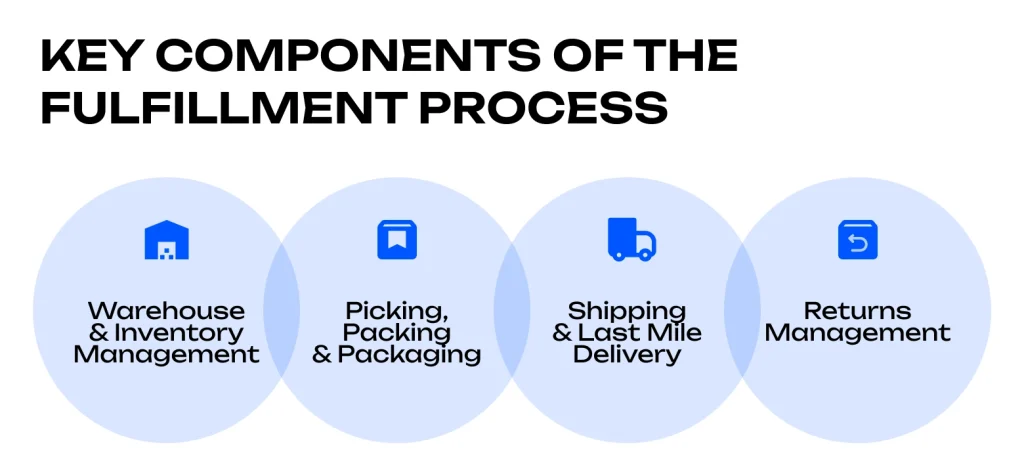

Key Components of the Fulfillment Process

A modern operation is built from several key components that work together as one system.

Warehouse, Warehousing and Inventory Management

The warehouse is the physical core of fulfillment. Here goods arrive from the factory, are checked against the receipt, and stored in defined locations. Good warehousing practice and accurate inventory management ensure that stock levels are correct and that customer orders can be processed quickly.

Inventory data flows back into the supply chain, helping teams plan production, set a competitive price and avoid both stock-outs and over-stocking. When inventory is wrong, every other part of the order fulfillment process suffers.

To learn more about how stock accuracy is maintained, explore stock control practices.

Order Fulfillment: Picking, Packing and Packaging

The heart of order fulfillment is the sequence often called “pick, pack, ship”. Once the system receives customer orders, staff start order picking: they walk the warehouse, locate ordered items, and bring them to a packing station. There the team handles packing and packaging – choosing the right box, adding fillers, inserts, documentation and, when needed, a printed payment confirmation or invoice.

This stage is where accuracy and speed matter most. Small layout changes, simple automation, or smarter routing inside the warehouse can increase efficiency and protect the value of every shipment. Done well, this part of the process reduces errors, returns and re-handling costs.

Shipping, Delivery and Last Mile Delivery

After an order is packed, labels are printed and the shipment enters the carrier network. Parcels are scanned, sorted, transported through regional hubs and handed to local couriers for last mile delivery. This is the point where the brand’s promise becomes visible to customers: they either get the parcel on the promised day, or they do not.

Proactive communication about order status, including last mile delivery tracking, is essential for managing expectations and strengthening trust.

Reliable partner carriers, smart routing and clear data flows make a big difference here. Delays, failed attempts or lost parcels quickly damage the customer experience and lead to more support request traffic from customers.

Returns Management: Closing the Loop

No company loves returns, but efficient returns management is one of the key components of a healthy fulfillment strategy. A frictionless return process improves retention, reduces customer frustration and increases trust. Businesses with efficient returns management typically see higher customer satisfaction and lower operational costs. Streamlined fulfillment provides a competitive edge in global markets. If you want to explore optimization options, see ecommerce returns optimization.

Fulfillment Services: What Providers Actually Do

Because these processes are complex, many businesses use third-party fulfillment services. A specialist provider will store your stock, connect your online shop to its systems, and take over day-to-day order processing. Third-party logistics (3PL) services can help improve operational efficiency without requiring significant time and money investments.

A typical fulfillment service provider is responsible for:

- warehousing and inventory control;

- inbound receipt and quality checks;

- order processing, picking, packing and labelling;

- arranging shipping and last mile delivery with local carriers;

- basic customer-facing tasks like handling returns requests.

Instead of investing money into their own facilities, companies tap into the provider’s network and pay for the capacity they use. This outsourcing model gives growing businesses a flexible way to enter new markets, test new products and scale up or down without heavy fixed costs.

INSIGHT: In practice, outsourcing does not mean giving up responsibility. The merchant is still responsible for the delivery promise, legal compliance and overall customer experience; the fulfillment partner simply executes the operational side.

For understanding real budget requirements, review fulfillment costs per order.

Why Fulfillment Is Important for Customer Experience

If marketing sets expectations, fulfillment is the act of keeping them. From the customer point of view, everything between the “order confirmed” email and the moment the courier rings the doorbell is part of the customer experience.

This is why many brands now treat fulfillment as a core part of their business strategy. Shorter lead times, transparent tracking, and fair shipping costs are features customers actively look for when choosing between online shops.

From a management view, this is where fulfillment is important and stops being a slogan. Brief inventory management reviews show whether the entire process matches customer expectations and business goals.

KEY POINT: Fast, predictable delivery and simple returns create a sense of control and reliability. Slow, confusing or error-prone processes create the opposite effect. Customers may forgive design mistakes more easily than they forgive broken delivery promises or missing items.

The Entire Process: From Click to Doorstep

Although each company operates differently, the entire process usually follows the same logic:

- A customer places an order in the online shop and completes the payment.

- The order management system checks inventory and reserves stock.

- Warehouse staff or robots start processing customer orders: they pick items, pack parcels and apply shipping labels.

- Parcels are handed over to carriers, shipped through the network and routed towards the correct country or region.

- Local couriers handle last mile delivery and hand parcels to customers within the promised time window.

- If needed, the returns management process begins and inventory management records are updated.

When all of these steps work as one efficient system, the company can scale volume, control costs and offer a consistently positive customer experience. For deeper understanding of internal flow, explore warehouse operations.

Fulfillment Strategy and Business Growth

A solid fulfillment strategy links daily operations with long-term business goals. It defines where warehouses should be located, which markets will be served from each point, which carriers to integrate, and how to balance costs against speed and reliability. A fulfillment strategy determines the decoupling point in the supply chain, impacting how firms manage inventory. Understanding different types of warehouses also may help.

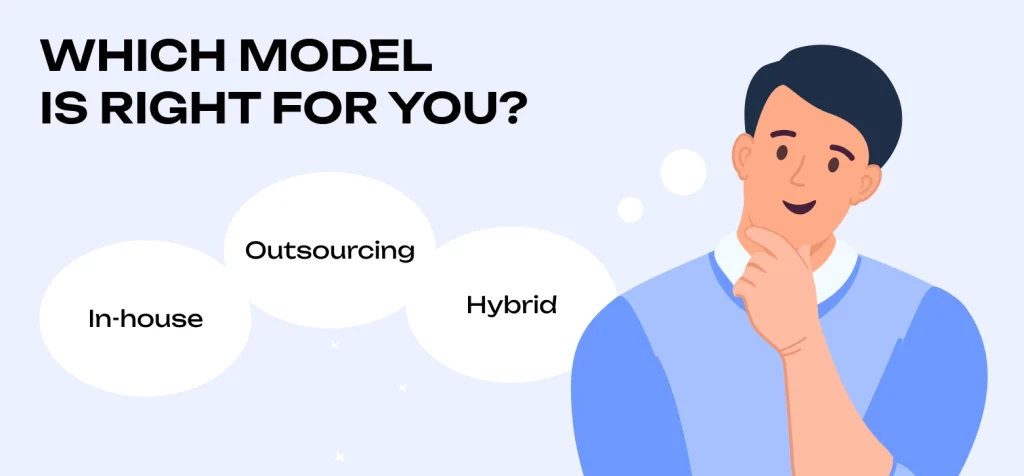

In-house vs Outsourcing

Some businesses decide to build everything in-house, investing in their own warehouse, warehousing equipment, systems and staff. Others choose outsourcing and work with a partner that already has a network, technology and local know-how. Many combine both approaches.

OUR ADVICE: In each case, ask yourself: which model will deliver orders accurately, on time and at a sustainable price, while freeing the team to focus on product, marketing and customer relationships? Then make a choice.

Fulfillment, Data and Continuous Improvement

Modern fulfillment depends heavily on data and technology. Warehouse and order management systems track every step of the flow, from goods receipt to final delivery. Dashboards show where parcels are, how quickly they move, and where errors or delays appear in the logistics network. Effective fulfillment systems integrate technology that reduces human error and prevents stockouts.

By watching these signals, companies can fine-tune processes: change carrier mix, adjust cut-off times, redesign picking routes or update packaging. Small improvements in speed, accuracy and cost per parcel compound over thousands of orders and can decide who wins in a competitive market.

At the same time, fulfillment data feeds back into the wider supply chain. It helps planners adjust production, refine stock strategy, and understand which products create the most support tickets or returns.

Beyond Operations: The Human Meaning of Fulfillment

There is also a softer meaning to the word. In everyday language, people speak about personal fulfillment when their work and life align with their values and wishes. For e-commerce founders and teams, building a reliable, efficient fulfillment engine can be part of that story.

INSIGHT: Being able to handle large request spikes, manage complex logistics, keep orders shipped on time and delivering value to customers brings its own form of satisfaction. In that sense, operational fulfillment and personal fulfillment are not so far apart.

Fulfillment with WAPI: Scalable, Data-Driven, Cross-Border

If your business is expanding into new markets or looking to improve operational efficiency, WAPI offers a fully integrated fulfillment solution built for cross-border e-commerce. WAPI connects online shops to a network of warehouses across Europe and manages the entire fulfillment cycle — from inbound receipt and storage to picking, packing, shipping, and returns.

A data-driven approach, real-time inventory visibility, and automated delivery routing help brands reduce costs, shorten delivery times, and maintain consistent service levels across regions. For companies balancing growth and operational stability, partnering with WAPI can turn fulfillment into a reliable competitive advantage.

Summary: A Simple Fulfillment Definition

Fulfillment in e-commerce is the coordinated set of logistics processes, systems and services that receive goods, store them, manage inventory, pack parcels, ship orders and handle returns. It links your online shop to the real world and determines how well your company can keep every delivery promise.

A clear understanding of what is fulfillment, and a thoughtful fulfillment strategy with strong components like warehousing, automation and smart carrier selection, helps businesses control costs, protect customer satisfaction and turn logistics from a headache into a genuine competitive advantage.

Community

Community